Creative companies propose more innovative and high quality designs to launch more competitive products.

The industrial market requires a variety of parts and metal parts to assemble equipment and systems; volume manufacturing and low costs, applications and designs in increasingly innovative and complex metal to introduce competitive products to market. But within the manufacturing process there are several steps that take time and errors may occur involving material losses, like the case of cutting and metal penetration. This can compromise the quality and price of the final product.

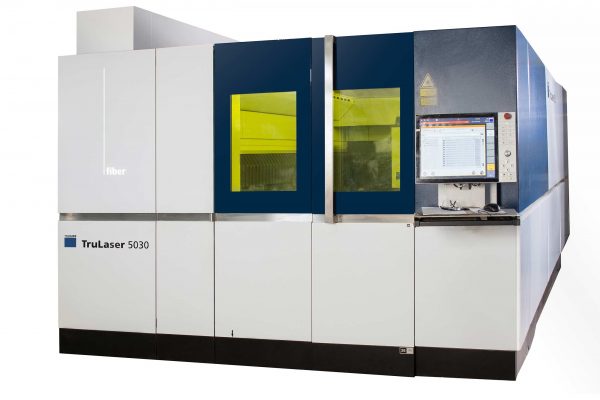

For this reason JJ Metales SAC has its equipment in the latest technology, as modern Japanese-made machine LASER, to perform various tasks requiring precision and quality, as well as speed and low cost.

Laser technology incorporated into the manufacturing processes of metal products brings many benefits and cutting holes, where the dimension is programmable from a few mils in diameter to any extent required. The laser can cut at high speeds, allowing to make many holes in a short time.